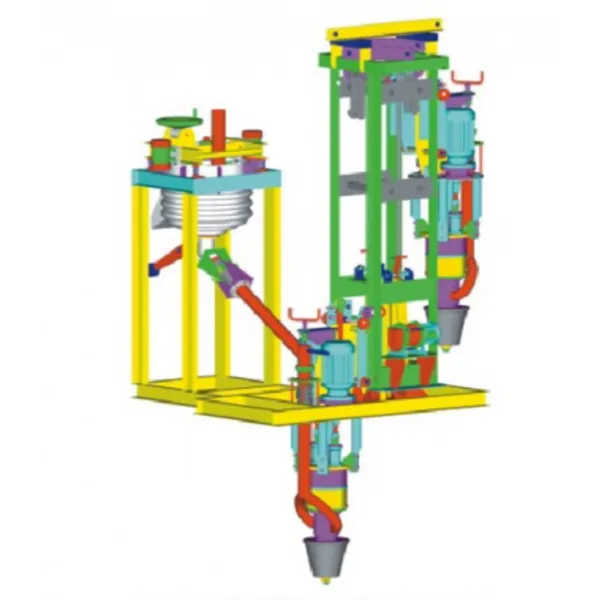

Tower Mixed Fertilizer Production Line

Compound fertilizer granulation solution with tower blending system

Tower Mixed Fertilizer Production Line

Compound fertilizer granulation solution with tower blending system

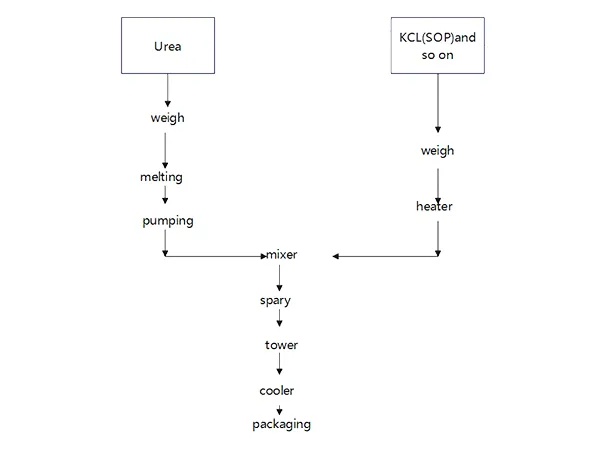

Tower blending is a widely used process for producing compound fertilizers through a molten-state system. Solid urea or ammonium nitrate is heated until it melts, or molten urea can be used directly after concentration. Phosphate, potash, fillers, and additives are then blended into this molten slurry. The slurry is sent into the blending tower, where it is sprayed down from the top of the tower. As it descends, the slurry interacts with rising gases, allowing for efficient heat exchange. During this process, the granules form while cooling down, resulting in smooth and durable fertilizer pellets. Once the granules reach the bottom of the tower, they are screened and surface-treated, ensuring high-quality compound fertilizers that are ready for use.

- Daily production capacity: 300-500 tons/day